WITOCG-14000 Optical Control System Software

WITOCG-14000

WITOCG-14000 Optical Control System Software

Hardware:

1. Imported Olympus microscopes, domestic metallographic microscopes, etc.

2.WITOCG-CCD 6 million pixel camera

Software:

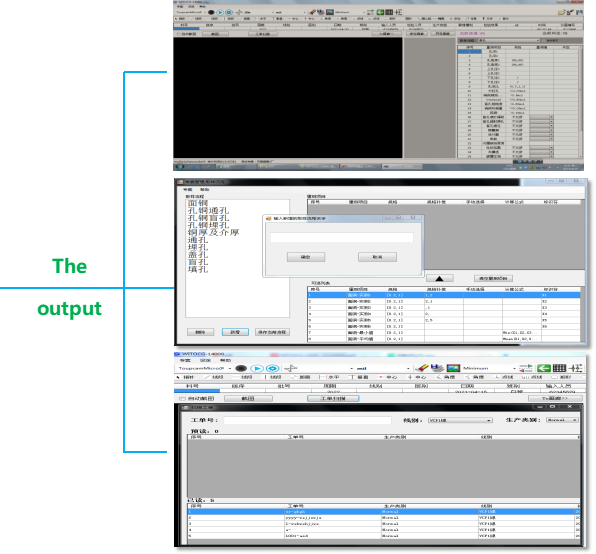

WITOCG-14000 was developed in response to Industry 4.0. This software can scan and identify work order information, customize projects, save pictures, export measurement data reports, and upload real-time data to internal systems.

1. The automatic acquisition of metallographic microscope system is developed and designed in response to customers' needs for Industry 4.0. It improves work efficiency, reduces operators and labor intensity, saves paper, reduces waste, and responds to the government's call for energy conservation, emission reduction and environmental protection. At present, the system has been put into use in Wuxi Jianding Technology Metallographic Slicing Laboratory, has achieved a good reputation and achieved the expected results.

2. Disadvantages of the old software for metallographic sectioning:

It turns out that the metallographic section specifications of different customers and different material numbers need to be printed on A4 paper to obtain the specifications one by one. During the test of metallographic section, one data needs to be tested and recorded manually, and the data records are temporarily archived on A4 paper. , until one metallographic section test is completed, and then manually judge whether the data is OK or NG (wasting a lot of paper and printing ink, manual judgment is inefficient and prone to misjudgment); after a batch of metallographic section tests are completed, the data is recorded in A4 The data temporarily archived on paper is manually input point by point into the computer for archiving, and then manually uploaded to the server. The work of recording data needs to be repeated. Test data is error-prone in manual recording and input into the computer, and is inefficient.

The format of the slice shipment report required by the customer requires manual reorganization of the data in the computer, and then prints it out and gives it to the customer along with the goods.

3.Automatic acquisition of metallographic microscope system advantages:

1. Automatically obtain slicing specifications from different customers and different material numbers through the network system (saving a lot of paper and printing ink).

2. During the process of testing metallographic slices, the software will simultaneously record the data of each test point (there is no need for personnel to repeatedly fill in the records to prevent input errors).

3. Automatically determine whether the data is OK or NG, and mark it with eye-catching colors (to prevent misjudgment and improve efficiency).

4. After each batch of metallographic slices is tested, the corresponding customer shipment report is automatically generated.

5. After each metallographic section is tested, it will be automatically uploaded to the server.

6. It can prevent missed tests, reduce duplication of work, and improve work efficiency.

7. It can prevent on-site personnel from cheating and the data can be traced.

Tel:+86 0512-57778597

Email:andy@witocg.com