WITOCG-9001 Intelligent Control System Software

WITOCG-9001

WITOCG-9001 Intelligent Control System Software

Name: Network Analyzer + Software Test System

Applicable Models:PNA P5027A Network Analyzer

PNA P5027A Network Analyzer

Applicable: PCB、F-PCB、CABLE(IPC-TM-650)

1. Testable type, characteristics and differential impedance test; required to measure insertion loss S21 function and S11VSWR function; (four ports)

2. The bandwidth requirement reaches 44GHZ (the bandwidth requirement can be upgraded according to customer requirements to cope with higher customer needs, the test accuracy is ±1%, and the resolution is 0.01Ps, the higher the better);

3. The interface is clear and friendly, and the structure is simple, making it easy for testers to get started and operate.

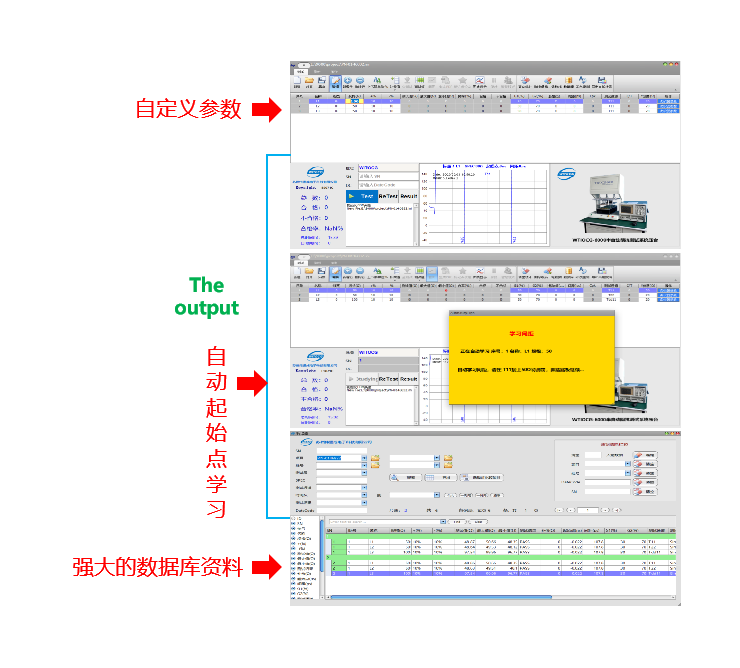

4. Customers can customize the test specifications, rise time, and batch number to facilitate customers' new product development and verification.

5. Previously created files can be retrieved for measurement directly (no need to recalibrate, saving time and improving work efficiency).

6. Automated testing can be realized. Through foot control, it is convenient for testers to operate and improve work testing efficiency, thus enhancing the competitiveness of customer products.

7. The test results can be automatically saved in the database, and test reports for different customers can be output. The reports include test data, waveform screenshots of the test instrument, and test waveform diagrams (Note: The specific percentage data of the interval range is displayed, making observation intuitive and convenient). It is convenient for customers to read the report and find problems directly from the report.

8. You can use the "smart mode" to automatically detect the length of different impedance lines and automatically provide the starting point and the corresponding test spacing.

9. The upper and lower limits can be switched between percentage and ohm values at will, and the compensation value can be automatically learned to improve test accuracy.

10. During the process of creating a new file, you can customize the starting point and the position of the open circuit point on the graph to ensure that the parameters of all instruments are consistent and are not affected by human judgment.

11. Supports reading instrument parameters directly from the instrument: such as automatically obtaining the starting point, spacing, sampling times, calibration record points, rise time, test channel, etc.

12. Calibration methods provided include: fast electronic calibration, mechanical manual calibration, and SKEW ordinary calibration, which can meet the needs of laboratories under different conditions.

13. Supports free switching of three languages (Simplified, Traditional, and English) to facilitate factory review by different end users.

14. S/N number input during the test process: supports barcode gun, QR code, and snap shot, saving personnel input time, ensuring accuracy, and improving efficiency.

15. After the test, the data file name storage method: supports barcode gun, QR code, and snapshot, saving personnel input time, ensuring accuracy, and improving efficiency.

16. Supports the display of real-time dynamic waveforms, making it easy to observe whether the contact is intact (Note: It is especially suitable for small-point testing in the test board). The test is convenient and the data is more accurate.

17. Supports instrument screenshots, intelligent generation of EXCEL, PDF, CVS and other report functions (note: customer data report format can be customized), which can quickly and conveniently produce reports without the need to re-layout the data report format, saving personnel input time, ensuring accuracy, and improving efficiency.

18. Comes with database query function: keyword query such as S/N number, project name, batch number, specification, operator, test result PASS/FAIL, test time, test cycle, etc.

19. It can ensure the accuracy and consistency of data, such as waveform display data (note: specific percentage data of the interval range is displayed, intuitive and convenient observation), instrument screenshot display data, and database data. The test data of the three are completely consistent.

20. Mainly developed to address the problems of tight testers and high mobility, and the long training period for operators of the old software system. The new system WITOCG-9000 only needs 1-2 hours of training to be able to work proficiently in production.

21. Can be upgraded: semi-automatic platform control system, SWITCH matrix switch control system, and supports 100 groups of differential impedance testing at the same time.

Tel:+86 0512-57778597

Email:andy@witocg.com